Emerging Technologies Shaping Warehouse Development in the US

I. Automation and Robotics

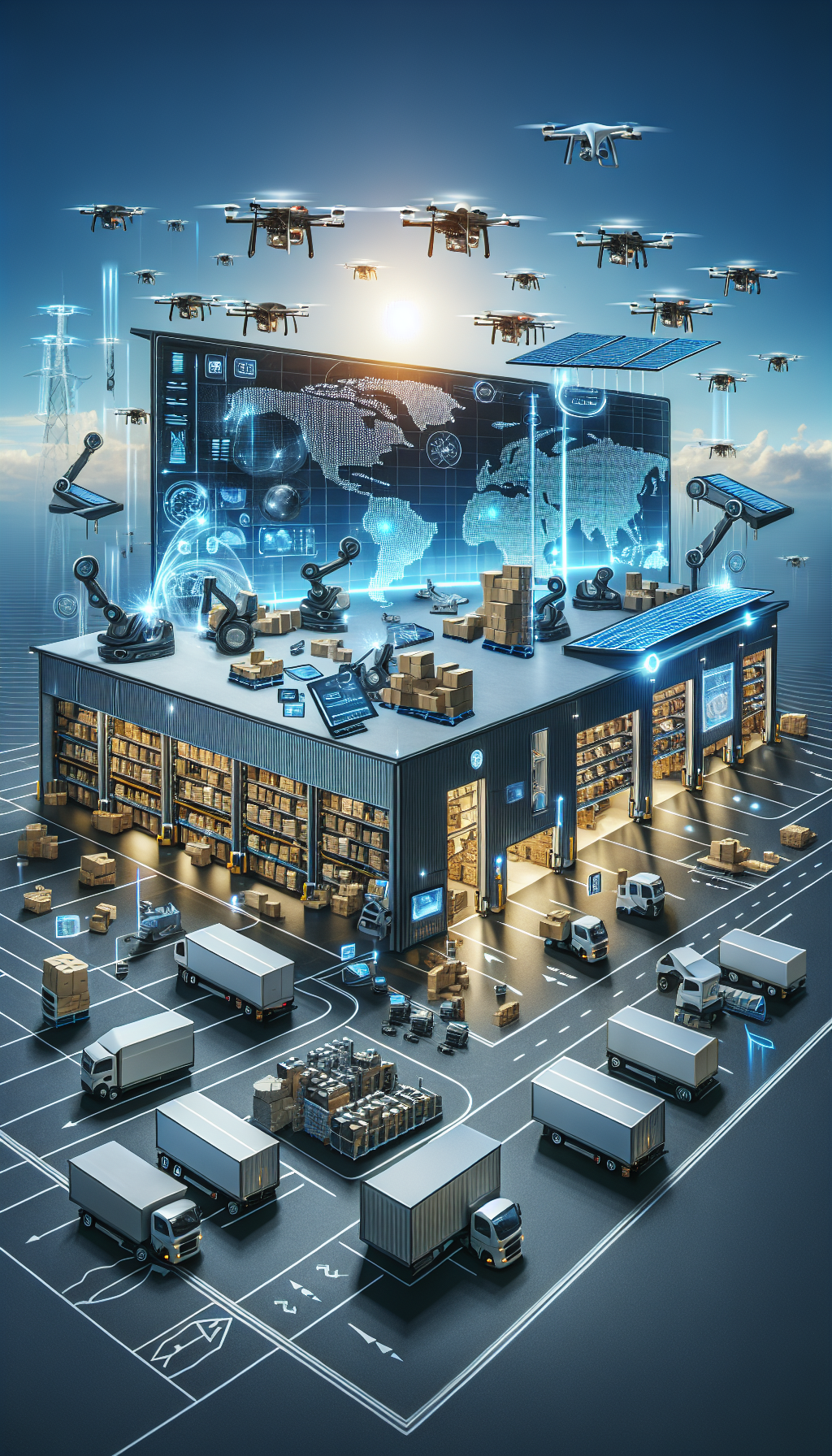

The warehouse industry is experiencing a seismic shift as automation and robotics emerge as central players in enhancing operational efficiency. Autonomous mobile robots (AMRs) are revolutionizing how goods are transported within warehouses. These robots can efficiently navigate complex layouts, reducing the need for manual labor. Companies like Amazon and Walmart have begun employing robotic systems to streamline picking and packing processes, significantly reducing order fulfillment times.

In addition to AMRs, automated sorting systems are becoming integral to warehouse operations. These systems leverage artificial intelligence (AI) to enhance sorting accuracy and speed, allowing warehouses to process larger volumes of goods with minimal errors. For instance, an AI-driven sorting system can classify products based on size, shape, and weight, optimizing storage space and accelerating retrieval times.

II. Internet of Things (IoT)

The internet of things (IoT) plays a critical role in modern warehouse development by enabling real-time tracking and monitoring of inventory. Sensors embedded in shelves and pallets provide continuous updates on stock levels, preventing stockouts and over-stock situations. This technology helps warehouse managers optimize inventory management, reducing carrying costs and improving customer satisfaction through timely deliveries.

Moreover, IoT devices can monitor equipment health, predicting maintenance needs before breakdowns occur. This predictive maintenance reduces downtime, ensuring that operations run smoothly. Data generated from IoT devices also offers insights into workflow efficiency, allowing businesses to identify bottlenecks and implement necessary improvements.

III. Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are increasingly being integrated into warehouse management systems (WMS) to enhance operational efficiency. Through advanced algorithms, AI can analyze vast amounts of data to predict inventory needs and optimize supply chain operations. For instance, machine learning models can forecast demand based on historical sales data and market trends, enabling warehouses to stock appropriately and react swiftly to changing conditions.

Additionally, AI-driven WMS can automate various tasks, such as order picking and packing, thereby minimizing human error and maximizing throughput. Intelligent systems are capable of learning from past performance, adjusting workflows autonomously to optimize resource allocation. This aspect not only increases productivity but also optimizes labor costs.

IV. Augmented Reality (AR) and Virtual Reality (VR)

Augmented reality (AR) and virtual reality (VR) technologies are gaining traction in warehouse training and operations. AR can assist workers by overlaying digital information onto their physical environment. AR devices help warehouse employees locate items quickly, enhancing picking accuracy, thus reducing time taken per order.

In employee training, VR provides immersive experiences that simulate warehouse environments. New hires can undergo realistic training scenarios, improving skill acquisition and retention. Such technologies reduce the learning curve while enhancing overall productivity.

V. Blockchain Technology

Blockchain technology is making significant inroads into warehouse management and logistics by enhancing traceability and security. By creating a decentralized and transparent ledger of transactions, blockchain allows all parties in the supply chain to access and verify information in real time. This transparency minimizes disputes and enhances trust between stakeholders, including suppliers, manufacturers, and distributors.

Furthermore, blockchain can streamline processes like returns and recalls, allowing warehouses to trace product history quickly. This traceability is paramount in regulated industries, such as pharmaceuticals and food, where compliance is essential.

VI. Drones

Drones are increasingly being utilized in warehouse operations for inventory management and monitoring. These flying devices can conduct stock checks in large warehouses quickly and accurately, significantly reducing the time spent on inventory counts. Equipped with cameras and scanners, drones can capture data and relay it to warehouse management systems, providing a real-time overview of stock levels.

Furthermore, drones are beginning to find applications in last-mile delivery, efficiently transporting goods from warehouses to retail outlets or directly to consumers. This capability alleviates traffic congestion and contributes to faster delivery times.

VII. Sustainable Technologies

The growing emphasis on sustainability is shaping warehouse development, prompting the adoption of green technologies. Energy-efficient materials in construction, such as insulated panels and solar panels, are gaining popularity. Warehouses are increasingly being designed to minimize carbon footprints through smart building practices.

Sustainable technologies also include automated systems for waste management and recycling. Implementing smart waste management systems enables warehouses to monitor waste generation and optimize recycling processes. This reduces operational costs while contributing to corporate social responsibility goals.

VIII. 3D Printing

3D printing technology is transforming warehouse logistics by enabling on-demand production of parts and products. Warehouses can stock raw materials instead of finished goods, significantly reducing inventory costs. This capability allows businesses to swiftly respond to customer demands without incurring the costs associated with overstocking or warehousing.

Additionally, 3D printing facilitates product customization, allowing warehouses to offer tailored solutions to clients. This rapid prototyping and production flexibility gives companies a competitive edge in a market increasingly driven by consumer preferences.

IX. Data Analytics

Data analytics is at the forefront of decision-making in modern warehouses. Advanced analytic tools enable managers to derive actionable insights from vast datasets generated during operations. By analyzing patterns in order fulfillment, shipping, and inventory management, businesses can optimize their logistics strategies.

Predictive analytics help warehouse managers anticipate changes in demand and adjust inventory accordingly. This proactive approach minimizes the risks of overstocking or stockouts, ensuring that operations remain efficient and responsive.

X. Modular and Flexible Warehouse Design

The need for agility in the supply chain has led to the trend of modular and flexible warehouse designs. These facilities are built with the capacity to adapt to changing business needs, allowing for easy reconfiguration as new technologies or processes are adopted. This flexibility is vital in an era of rapidly changing consumer demands and competitive pressures.

Innovative storage systems, such as movable shelving and dynamic racking, enable warehouses to increase storage capacity while facilitating quick reconfigurations. This adaptability ensures that warehouses optimally utilize space and resources, enhancing operational efficiency.

In the evolving landscape of warehouse development, the integration of these emerging technologies continues to redefine operational standards, increase efficiency, and provide competitive advantages for businesses across the US. With ongoing advancements, the future of warehouses looks increasingly innovative and dynamic.