Navigating the Future of Logistics Real Estate with Advanced Robotics

The Evolution of Logistics Real Estate

The logistics real estate sector has undergone a revolutionary transformation over the last few decades. Driven by e-commerce growth and consumer demand for faster delivery times, the sector has seen substantial investment in warehouses and distribution centers. The rise of omnichannel retailing has made distribution networks more complex, driving the need for larger facilities and efficient designs. As logistics real estate evolves, advanced robotics plays an increasingly crucial role in enhancing operational efficiency and space utilization.

The Role of Advanced Robotics in Logistics

Robots are redefining how logistics companies operate. Automated systems designed to handle inventory management, order fulfillment, and shipping are no longer a luxury; they have become a necessity for the competitive landscape of the logistics industry. These robotic solutions range from autonomous mobile robots (AMRs) that transport goods within warehouses to automated guided vehicles (AGVs) that navigate pre-defined paths.

-

Autonomous Mobile Robots (AMRs)

AMRs utilize sophisticated sensors and artificial intelligence (AI) to navigate through dynamic environments. Unlike traditional warehouse systems, AMRs can adapt their paths to avoid obstacles and optimize routes for faster delivery times. In a logistics real estate setup, the use of AMRs can lead to reductions in labor costs and the minimization of human error during the order-picking process. -

Automated Guided Vehicles (AGVs)

AGVs are programmed to follow specific routes often marked by magnetic strips or laser guidance. These vehicles are instrumental in transporting products from one part of a warehouse to another. By leveraging AGVs, logistics companies can streamline operations and significantly decrease delivery times, which is essential for meeting small delivery windows demanded by consumers. -

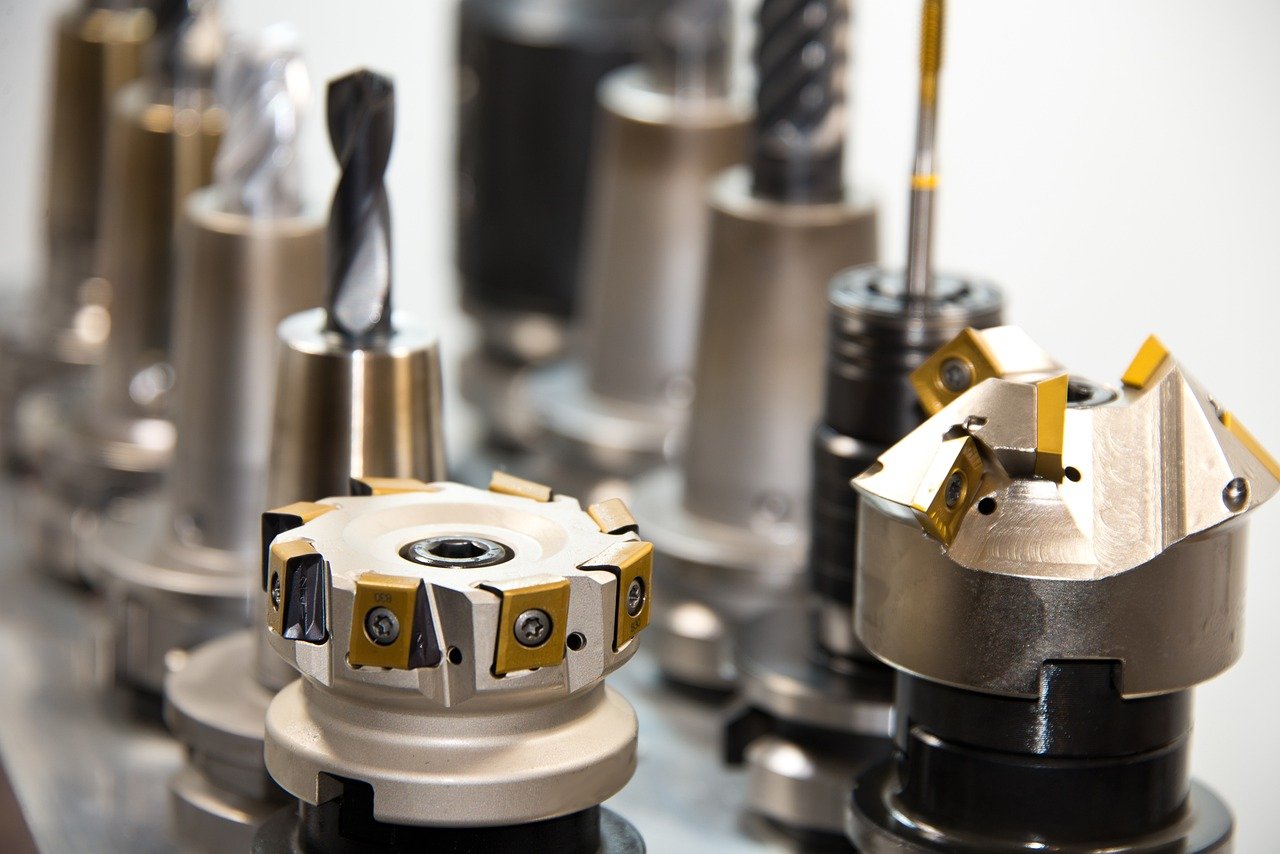

Robotic Picking Systems

One of the most labor-intensive tasks in logistics is order picking. Robotic picking systems utilize robotic arms equipped with sophisticated sensors and cameras to recognize, pick, and place items in packaging or containers. Such systems increase accuracy, reduce waste, and allow warehouses to handle high volumes of orders with minimal manpower.

Optimizing Space Utilization with Robotics

The increasing demand for logistics real estate comes with challenges related to space optimization. Advanced robotics allows companies to maximize their storage capabilities, reducing overhead costs associated with unnecessary space.

-

Vertical Storage Solutions

Robotic warehousing often incorporates vertical storage systems that allow for denser packing of goods. Automated systems can reach high shelves without putting human workers at risk. By optimizing the vertical space in warehouses, logistics companies can store more products without expanding facility footprints. -

Dynamic Slotting

Advanced robotics can assist in dynamic slotting processes, where inventory is adjusted in real time based on demand patterns and seasonal fluctuations. This agility reduces the time needed to find items and enhances overall workflow. -

Real-time Inventory Management

AI-powered robotics can link with inventory management systems to provide real-time stock levels and performance analytics. Having accurate inventory information allows firms to react quickly to changes in demand, thus optimizing their logistics operations.

The Impact on Workforce Dynamics

While the integration of robotics in logistics offers significant advantages, it also creates a paradigm shift in workforce dynamics. The traditional roles in warehousing are evolving, leading to the creation of new job classes centered around robotics management and maintenance.

-

Up-skilling and Reskilling Employees

As robots take over repetitive and hazardous tasks, the workforce must adapt. Companies need to invest in training programs to help employees transition to roles in robot operation, programming, and preventive maintenance. -

Collaboration between Humans and Robots

The future of logistics will not entail robots replacing humans entirely. Collaborative robots, or cobots, work alongside human employees, assisting in tasks that require precision or heavy lifting while allowing workers to focus on more strategic roles. -

Safety and Ergonomics

The implementation of robotics in logistics environments significantly improves workplace safety. Tasks traditionally viewed as dangerous or strenuous, such as lifting heavy items, can be delegated to robots, reducing workplace injuries and improving overall employee satisfaction.

Challenges in Implementing Robotics

Despite the apparent benefits, the integration of advanced robotics in logistics real estate is not without challenges.

-

High Initial Investment

The upfront costs associated with purchasing and implementing robotic technology can be substantial. Organizations must weigh these initial costs against the long-term benefits and savings that automation will provide. -

maintenance and Technical Expertise

Maintaining advanced robotics systems requires specialized technical expertise. Companies must ensure that their workforce is equipped with the necessary skills or be prepared to contract specialized technicians adequately. -

Technological Integration

Integrating robotic systems with existing logistics and warehouse management systems poses another challenge. Legacy systems may require significant upgrades or full replacements to accommodate new technologies effectively.

The Regulatory Landscape

As robotics in logistics continue to grow, the regulatory landscape is evolving. Understanding the legal implications surrounding robotics is critical for logistics real estate stakeholders.

-

Safety Regulations

Robotic systems must comply with occupational safety regulations. Ensuring that robots do not pose risks to human operators requires rigorous safety standards. -

Data Security and Privacy

Robots collect vast amounts of data, raising concerns about data security and privacy. Companies need to implement strong digital security measures to protect sensitive data from breaches. -

Environmental Regulations

The logistics sector is under scrutiny for its environmental impact. Robotics can contribute positively by optimizing energy use; however, companies must still adhere to environmental regulations as they implement automation technologies.

Future Innovations in Robotics and Logistics Real Estate

The future of logistics real estate will likely be marked by continued innovation in robotics and automation.

-

AI and Machine Learning

AI algorithms will increasingly guide the operations of robotic systems, streamlining processes and generating predictive analytics that enhance decision-making. -

Drones for Last-Mile Delivery

As urbanization increases and e-commerce continues to thrive, drones will play a critical role in reducing last-mile delivery issues, allowing for rapid and efficient order fulfillment. -

Integrating IoT with Robotics

The Internet of Things (IoT) will create smarter warehouses, enabling robots to communicate with other systems, share information, and further enhance operational efficiency. -

Sustainability Initiatives

As businesses become more environmentally conscious, robotic solutions focused on sustainability, such as energy-efficient systems and eco-friendly warehouse designs, will lead the way in logistics.

In summary, advanced robotics is not just a trend in logistics real estate; it represents a monumental shift that will redefine efficiency, workforce dynamics, and operational strategies. As the landscape continues to evolve, adopting and adapting to these technologies will be critical for businesses looking to thrive in an increasingly competitive environment.